Precision In Innovation

Engineering Excellence

That Drives Australian

Industry Forward

At Apollo Engineering, we don’t just manufacture parts; we craft solutions.

30 YEARS

INDUSTRY EXPERIENCE

Decades of Dedication

Your Partner in Precision Engineering Excellence

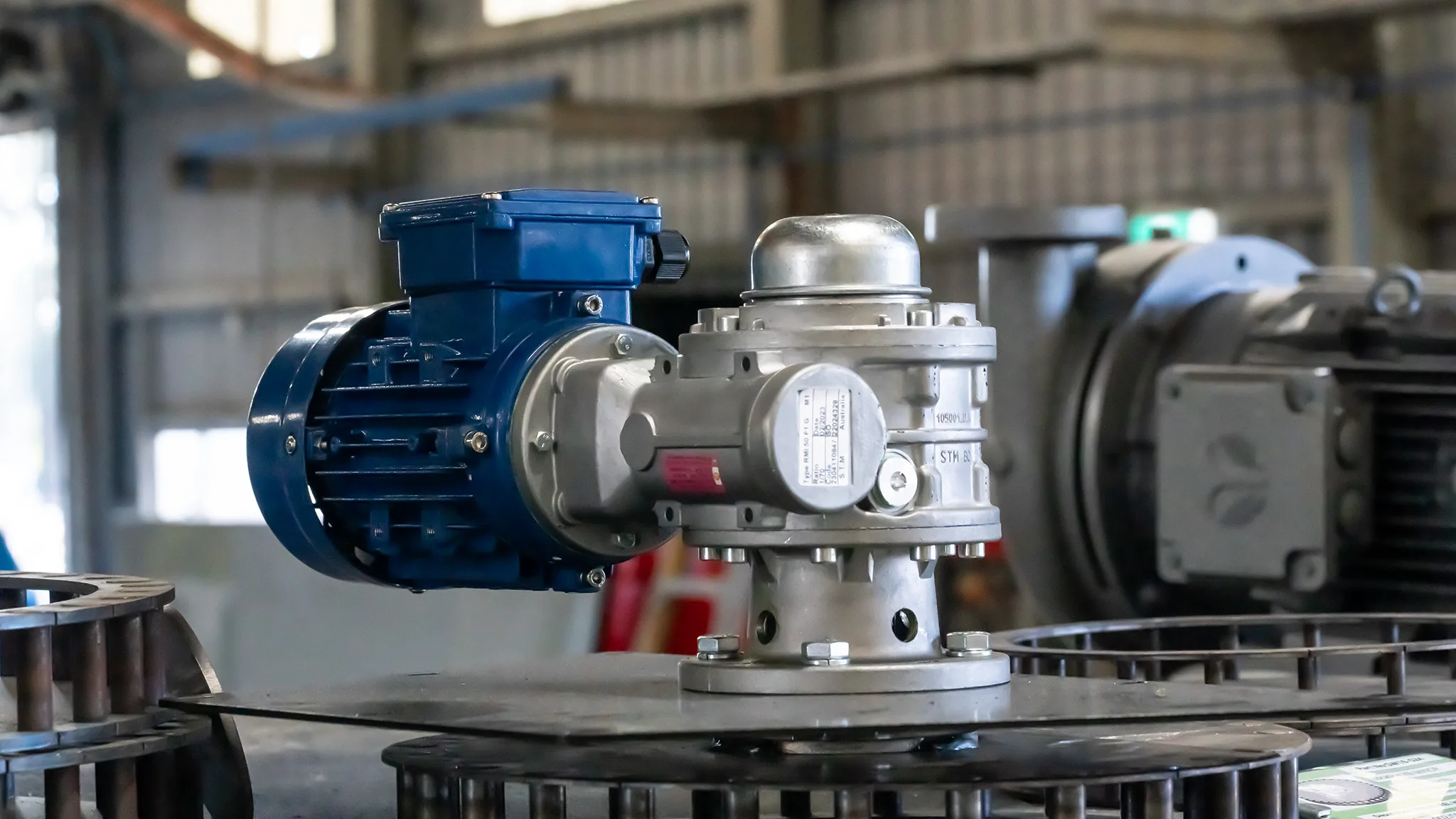

Founded on a commitment to excellence, Apollo Engineering has established itself as a leader in precision manufacturing across multiple industries. Our sophisticated facility in Northern NSW Tamworth, Regional NSW, utilises the latest manufacturing with automation technology to craft high-quality components, assemblies, and complete systems that meet the most demanding specifications.

We specialise in transforming complex engineering challenges into simple, efficient solutions. With capabilities spanning from prototype development to large-scale production, Apollo delivers the perfect balance of innovation, quality, and value.

Tailored Solutions

Our

Services

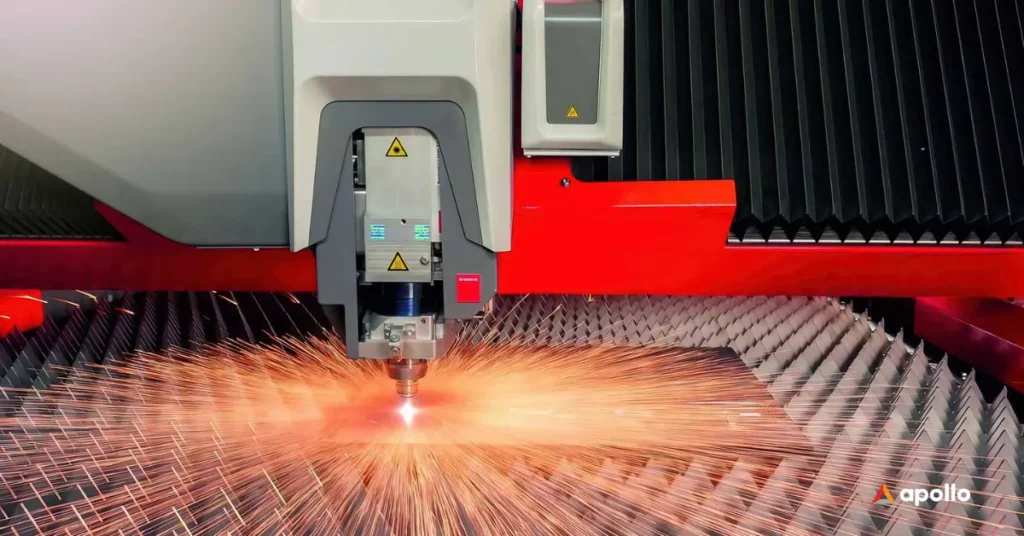

Need precise cuts and folds? Apollo Engineering’s laser cutting and press services are designed to deliver unmatched accuracy and speed. Whether you’re dealing with small prototypes or large-scale production runs, our advanced laser technology ensures clean, consistent results.

Apollo Engineering offers precision CNC machining services tailored to meet the most demanding industrial requirements. Our machining facility is equipped with advanced turning and milling centres capable of handling both high-volume production and one-off components.

We work with a wide range of materials — including mild steel, stainless steel, aluminium, and specialty alloys — and provide end-to-end support from CAD/CAM programming to final inspection. Our experienced team ensures tight tolerances, high repeatability, and a consistent standard of quality across every job.

Apollo Engineering delivers end-to-end manufacturing solutions, from precision fabrication to final assembly. We work with both light gauge materials and heavy-duty steel to produce components and structures suited to a wide range of industrial applications.

Our in-house capabilities include CNC cutting, folding, rolling, welding, and precision CNC machining — enabling tight control over quality and lead times.

We also offer high-quality surface preparation, spray painting, and finishing services to ensure every product meets both functional and visual requirements. Full assembly and testing are available as part of our turnkey service.

We offer professional industrial finishing services through our large spray and bake booth, measuring 11m (L) x 6m (W) x 4.5m (H). It is purpose-built to accommodate large machinery, fabricated structures, and complex components.

In addition to spray painting, we also offer blasting and powder coating to meet a wide range of project requirements.

Why Choose Apollo

Engineering Excellence That Sets Us Apart

Choosing Apollo Engineering means partnering with a team dedicated to your success.

30+ Years of Expertise

Decades of experience in engineering, machining, and fabrication ensures your project benefits from unmatched knowledge and skill.

End-to-End Capability

From prototype to production, Apollo handles every aspect of your project with precision and care, streamlining the process and ensuring consistent quality.

Quality Commitment

Our dedication to premium quality and client satisfaction drives everything we do, resulting in products that exceed expectations and perform reliably.

Industry-Leading Design

Combining technical expertise with innovative thinking, we create solutions that address complex challenges with elegant simplicity.

Cutting-Edge Technology

Our investment in the latest automated technologies allows us to handle projects of any scale while maintaining competitive pricing and exceptional quality.

SPECIALIZED SOLUTIONS

Industry-Leading Products Built for Performance

Apollo Engineering brings decades of expertise to our product range, developing specialised industrial solutions that deliver exceptional performance in demanding environments. Each product is designed with precision, built with quality materials, and optimized for efficiency, durability, and ease of maintenance.

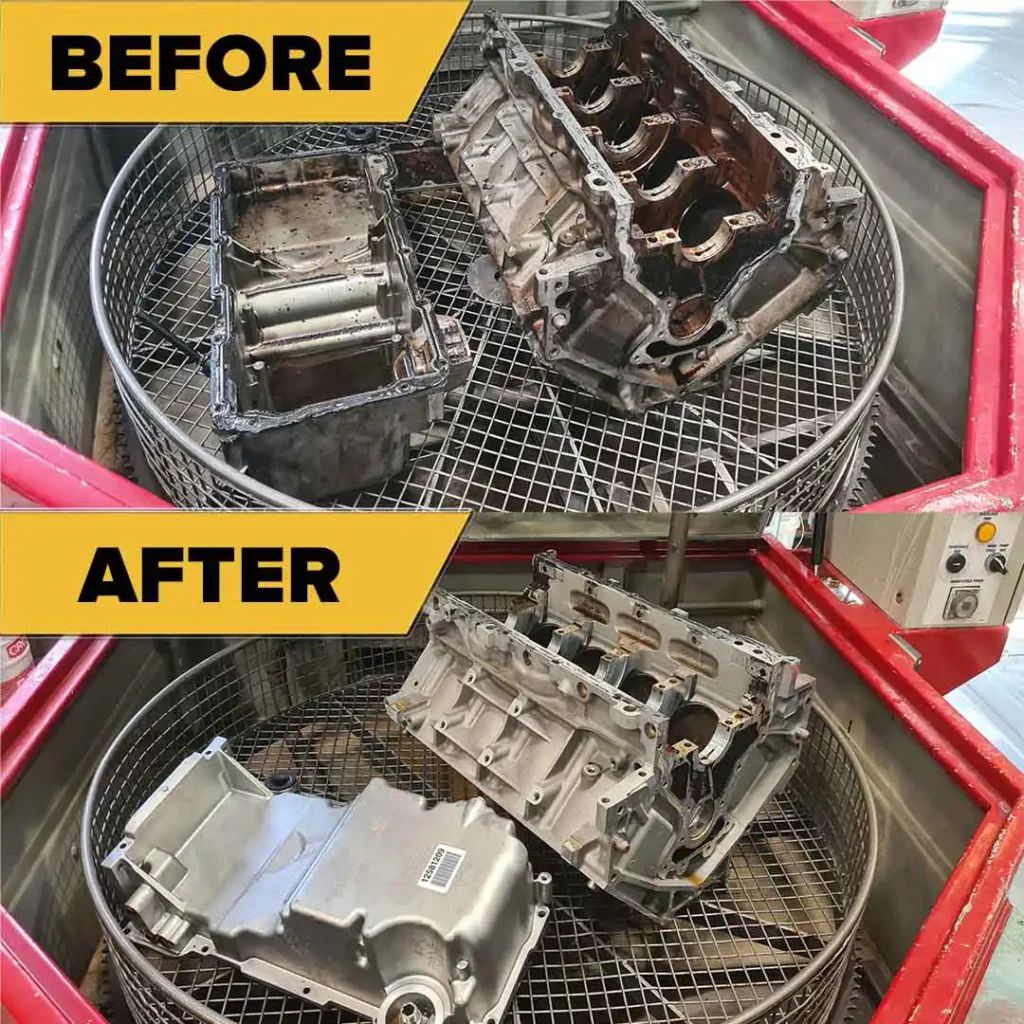

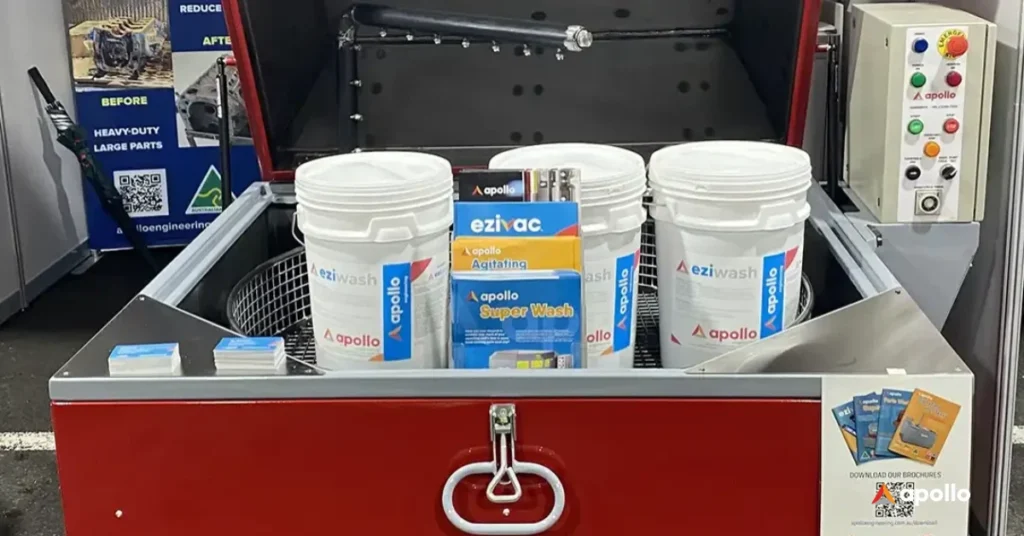

Apollo’s renowned cleaning systems set the industry standard for efficiency and reliability. Our range includes standard Parts Washers, Automated Parts Washers, and Hot Tanks, all engineered to deliver superior cleaning performance while maximising operational efficiency and minimising environmental impact.

Our Westate Pumps provide reliable, efficient irrigation solutions designed for Australian conditions. Built with durability and performance in mind, these systems deliver consistent results in even the most challenging environments.

The EziVac industrial wet vacuum combines powerful performance with robust construction to handle the toughest cleaning challenges. Designed for efficiency and ease of use, it’s the perfect solution for industrial cleaning requirements.

The innovative Biofeed waste processing system transforms waste management challenges into efficient, sustainable solutions. Engineered for reliability and performance, these systems help businesses reduce environmental impact while optimising operational efficiency.

News

This wasn’t just another year of getting the job done....Continue Reading

Apollo Engineering has added a manual parts washer to its...Continue Reading

Powering National Capability from Regional NSW A significant conversation is...Continue Reading

Shipping to South Africa: Export-Modified SW1612RD Parts Washer Apollo Engineering,...Continue Reading

Where Engineering Meets Art: Showcasing Adam Humphreys’ Sculptures At Apollo Engineering,...Continue Reading

Boost Production & Save Costs with our Parts Washers Range...Continue Reading

The Ultimate Guide to Choosing the Right Part Washer for...Continue Reading

2024: A Year in Review Milestones, Breakthroughs, and Accomplishments As...Continue Reading

Apollo Engineering Wins Manufacturer of the Year at HMA’s 20th...Continue Reading

Apollo Showcases High-Quality Industrial Cleaning Machines at METS India Apollo...Continue Reading

NSW Premier Chris Minns Tours Apollo Engineering We were honoured...Continue Reading

Introducing Apollo Engineering’s Advanced Industrial Cleaning Solutions: EziWash, EziClean, and...Continue Reading

Apollo Engineering Provides Young Aussies with Experience & Apprenticeships Play...Continue Reading

Streamlining Industrial Processes for Maximum Efficiency and Cost Savings In...Continue Reading

Growing the business with speed and efficiency Apollo Engineering. has...Continue Reading

Zimbabwean Migrants grow Apollo Engineering Tamworth, NSW Tamworth manufacturer, Apollo...Continue Reading

Why Use Engineering and Manufacturing Services in Australia? Are you...Continue Reading

Apollo Expansion Project 2023 New Engineering Workshop in Tamworth In...Continue Reading

Contact us today for a consultation or quote.

Discover how Apollo Engineering can bring your vision to life with precision, efficiency, and unwavering quality.